Brake system abs. How anti-lock braking system works

When braking. The main purpose of the system is to maintain the stability and controllability of the car (the braking distance in some cases may be longer than without the ABS system)

Story

For the first time, the problem of wheel blocking during braking was revealed on a railway car, since blocked wheels have a significantly lower braking effect, and a wheel rim develops a wear that reduces the driving performance of a car or locomotive. In addition, with blocked wheelsets, the likelihood of derailment increases significantly. The problem was solved by the use of automatic brake force regulators, known today as cargo auto mode. On electric trains and trams, where the service braking is electric, the blocking of the wheels is prevented by electric and electronic systems, which automatically regulate the excitation current of traction motors operating during braking in the generator mode. Such systems have been known since the 1920s. Also in the 1920s, the first ABS appeared for installation on aircraft chassis. Here it was necessary to solve the problem of aircraft controllability during the run along the runway. The first products were created by the French company Avions Voisin, a manufacturer of automobiles and aircraft.

In those days, most cars had mechanical brakes with a cable drive and demanded from the driver a significant physical strength, in other words, it was necessary to press hard on the brake pedal, thereby causing the wheels to lock, which, in turn, had a negative effect on the car's handling. Later, hydraulic brakes with a vacuum booster appeared, but this system did not solve the problem of wheel locking.

In 1936, Bosch patented a technology to prevent wheel lock when hard braking. But in practice, this idea could not be realized due to the lack of digital electronics in those years, which would allow reacting to blocking of the wheels in a split second. The situation changed in the 1960s with the advent of semiconductor technology, which gradually reached the automotive industry. But the first samples of ABS, which appeared in 1971 on one of the models of the General Motors concern, turned out to be even dangerous, since they did not solve the problem of jamming of the front drive wheels.

The first truly workable ABS was invented by the Germans. In addition to Bosch, since 1964, Teldix GmbH has begun work on the creation of ABS. Her engineer Heinz Lieber developed fundamentals future ABS. He later became head of the Daimler-Benz electrical and electronics department and in 1970 Daimler-Benz solemnly announced the creation of the first workable ABS. The system, called "ABS 2", consisted of an electronic controller, speed sensors mounted on each wheel, and two or more hydraulic valves in the brake circuit. The system worked on data on the difference in the speeds of rotation of different wheels: if they rotated at different speeds, then the controller, dosing the braking force, equalized the rotation speed. After that, the system made it possible to increase the braking force.

Comprehensive tests of this system revealed one significant drawback - the unreliability of electronic components. At the suggestion of Daimler-Benz, Bosch engineers were involved in the project, who worked independently from Lieber and gained vast experience in the field of automotive electronics.

Thus, Lieber's successful ideas and the vast experience of Bosch engineers in the development and production of digital electronic components were combined to work on the creation of a serial anti-lock braking system. In the mid-1970s, ABS began to be installed optionally (at the request of the client and for an additional fee) on executive class cars, and since 1978 it has been standard on two German cars - Mercedes Benz W116 (S-class) and BMW 7-series, moreover the cost of the system at that time was approximately 10% of the cost of the entire car. Since July 2004, every new car sold in the European Union has been equipped with ABS as standard.

The principle of operation of the ABS

The coefficient of sliding friction is much lower than the coefficient of static friction. Therefore, the braking distance with the wheels locked (sliding friction: the wheels slide on the surface) will be greater than the braking distance with the wheels still rotating (static friction: the tire at the point of contact with the road is at rest relative to it). In this case, the brakes provide a force slightly less than what is required to completely block the wheel. With sufficient experience, the driver is able to feel this effort himself, and if the wheels are blocked, he slightly weakens the pressure on the brake pedal, but at the same time he is not able to reduce the pressure and braking force on one, blocked wheel. The ABS system monitors the rotation of the wheels and, if they are blocked, slightly reduces the pressure in the brake system to allow the wheel to turn, and then again increases the compression force. In this way, intermittent braking is achieved, which makes it possible to correct the vehicle's course under extreme braking conditions.

System device

ABS consists of the following main components:

- speed or acceleration (deceleration) sensors mounted on the wheel hubs vehicle;

- control valves, which are elements of the pressure modulator, installed in the line of the main brake system;

- a control unit that receives signals from sensors and controls the operation of the valves.

This process is repeated several times (or several tens of times) per second, in 2008, according to experts "Behind the wheel", the average ABS worked 20 times per second.

ABS performance

The main task of the ABS is to allow the driver to maintain control over the vehicle during emergency braking, that is, it remains possible to perform quite sharp maneuvers directly in the process of braking. The combination of these two factors makes ABS a very significant plus in ensuring the active safety of vehicles.

An experienced driver can effectively brake without using ABS, controlling the moment of wheel stall on his own (most often this braking technique is used by motorcyclists) and weakening the braking force on the verge of blocking (braking is intermittent in this case). The effectiveness of such braking can be comparable with braking when using a single-channel ABS. Multi-channel systems in any case have the advantage that they can control the braking force on each individual wheel, which gives not only effective deceleration, but also a stable behavior of the vehicle in difficult conditions uneven grip of the wheels with the road surface.

For an inexperienced driver, having ABS is better in any case, as it allows emergency braking in an intuitive way, simply by applying maximum force to the brake pedal or handle while maintaining maneuverability.

Under certain conditions, the operation of the ABS may increase the stopping distance. For example, when using car tires with insufficient road grip (for example, when driving in winter with summer tires). Also, on loose surfaces such as deep snow, sand or gravel, wheels that are blocked when braking begin to dig into the surface, which gives additional deceleration. Unlocked wheels brake much more slowly under these conditions. In order to be able to effectively brake in such conditions, the ABS on some car models is turned off. In addition, some types of ABS have a special braking algorithm for loose surfaces, which leads to numerous short-term wheel locks. This braking technique allows you to achieve effective deceleration without loss of control, as with a full lock. The type of surface can be set manually by the driver or can be determined automatically by the system, by analyzing the behavior of the car or using special sensors for determining the road surface.

Emergency Brake Assist

Help system for emergency braking(SPET) detects emergency braking, brings the pressure in the brake system to a maximum and holds it there until the car comes to a complete stop. SPET can be implemented using electronic components or hydraulics. When detecting emergency braking, the following are taken into account:

- current vehicle speed;

- the speed at which the brake pedal is pressed;

- force (depth) of pressing the brake pedal;

- distance to the vehicle in front;

- and other parameters (for example, the proximity of a traffic light).

Studies have shown that a significant proportion of drivers in an emergency either do not fully depress the brake pedal or release it at some point. Because of this, the braking distance is longer than it could be with the pedal fully depressed. SPET was developed to solve this problem.

Emergency braking is a type of braking used by vehicle drivers more and more often, as it is dictated by the constant complication of modern road conditions. However, the effectiveness of such braking can be reduced to almost zero in the event of blocking of the wheel (s) of the vehicle. It stops the perception of lateral forces, the impact of which is designed to keep the car on a certain trajectory set by the driver. The vehicle not only loses controllability, but also stability, which in 90% of cases leads to its breakdown into an uncontrolled skid.

ABS brakes, named after the first letters of the Antilock Brake System technology, are functionally designed to maintain control of the vehicle during braking by preventing the wheels from locking. The result of using this system is an increase in braking efficiency, a decrease in the braking distance of the car, both on dry and wet road surfaces, an improvement in maneuverability, etc. The undoubted advantage of the "ABS" system can be considered a reduction in rubber wear, as well as ensuring its (wear) uniformity.

The main disadvantages of the anti-lock braking system include an increase in the braking distance of the car on surfaces with a loose structure: gravel, sand, snow, etc.

So, let's summarize what has been said. The functionality of the system that prevents blocking of the wheel (wheels) during emergency braking provides:

Effective vehicle braking on slippery (wet) road surfaces.

Prevention of the occurrence of "uncontrolled" drift.

Sufficient driver control over the car.

The design of the ABS brake system

The modern wheel lock prevention system consists of three main groups of elements:

Sensors (wheel speed and brake light switch).

Actuators (exhaust pump, hydraulic distributor, or modulator equipped with solenoid valves, signal lamps).

A control unit (ECU) that receives information from sensors and sends commands to actuators.

As it is easy to understand, the actuators, or modulators, are controlled by adjusting the pressure in the brake circuits of the wheels. At the same time, much attention is paid to the speed of information transfer from sensors located, as a rule, on the wheel axle, to the control unit.

The hydraulic distributor is a series of solenoid valves that control the amount of pressure in the system and are enclosed in a rugged housing.

central block electronic control, or "ECU", - two microcontrollers interacting with each other that control each other's work. Working programm the control unit includes several algorithms of operation, the main of which is the state of the brake system, depending on information about the wheel rotation parameters

The principle of operation of the anti-lock braking system

The vehicle's anti-lock braking system functions as follows. At the moment of braking, the brake fluid enters the inlet channels of the hydraulic distributor. The solenoid valves are open, and the working fluid is freely supplied to the wheels of the car. When information is received from the sensor about a critical change in the speed and position of the wheel, the control unit closes the electromagnetic valves, stopping or limiting the flow of brake fluid to the wheel brake mechanism. After the wheel lockup stops (based on information from the wheel sensors), the ECU returns the solenoid valves to their original position, thereby resuming the supply of brake fluid to the wheel brakes.

The driver of the vehicle, in addition to the banner on the control panel, signaling the inclusion of the ABS system, feels the brake pedal shocks caused by the rapid opening and closing of the modulator solenoid valves.

Features of operating a car equipped with a wheel lock prevention system

The operation of a vehicle with an ABS system has certain features and requirements, the observance of which will ensure the duration and stability of its (system) functioning:

Avoid connecting your vehicle's battery to another vehicle's battery (so-called "lighting").

When carrying out welding work on the car body, disconnect the contacts leading to the elements of the ABS system.

Periodically check the technical condition of the generator contacts.

Eliminate the disconnection of electrical connectors when the power plant is running or the ignition is on.

The electronic control unit "ECU" should not be exposed to prolonged exposure (no more than 2 hours) to high temperatures (not higher than 850C).

Novice motorists often panic when a banner lights up, signaling a failure of the vehicle's anti-lock braking system. In this case, remember the following:

a) The performance of the vehicle's braking system is independent of the performance of the ABS.

b) Flashing banner - a symptom that indicates a malfunction in the ABS system caused by a wiring fault.

c) Turning on the banner may be caused by low voltage (less than 10.5 V) in the car network.

d) out of order ABS system brakes are changed to a service station whose employees have the appropriate qualifications, equipment and skills.

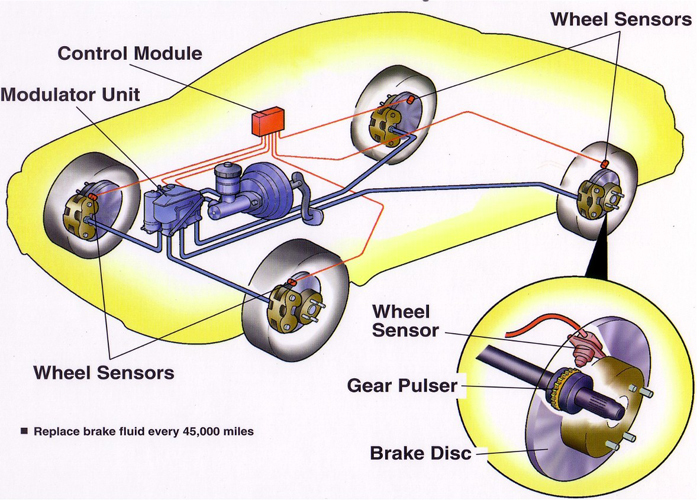

Location of anti-lock braking system components.

Hard braking on slippery roads can cause problems. Anti-lock braking system (ABS) takes over this action and saves your nerves. In fact, on slippery roads, even a professional driver cannot brake as quickly without ABS as the average driver with it.

In this article, we will look at anti-lock braking systems - why do we need them, how they are arranged, how they work, what they are, and what problems can arise when using them?

ABS system

In theory, anti-lock system set up quite simply. If you are skidding on ice, you will see the wheels spin, but there is no traction. This is due to slippage of the bearing area of the wheel on the ice. The anti-lock braking system prevents the wheels from locking up and spinning, which gives you two benefits: Stopping is faster and you keep control of the car during the stop.ABS includes the following components:

- Speed sensors

- Pump

- valves

- Control block

Speed sensors

The anti-lock braking system needs to track the moment that is borderline with the wheel lock. Speed sensors mounted on each wheel, or in some cases, on the differential, read this information.valves

The braking system has valves for each brake controlled by the ABS. In some systems, the valve has 3 positions:- In position 1 the valve is open; pressure from the master cylinder is transferred to the brake.

- In position 2, the valve blocks the line, isolating the brake from the master cylinder. This prevents pressure from building up when the brake pedal is pressed harder.

- In position 3, the valve slightly reduces the pressure in the brake.

Pump

Because the valve can weaken the pressure of the brakes, it is necessary to somehow force it to its original position. For this, a pump is used; when the valve bleeds the pressure in the line, the pump pumps it up to the required level.Control block

The control unit is a computer. It monitors speed sensors and controls valves.  ABS pump and valves

ABS pump and valves

ABS operation

Exist various options algorithms and their combinations for ABS control. We will consider the principle of operation of the most simple system.The control unit continuously reads the readings of the speed sensors. It monitors for any slowdowns that are not normal. For example, before a wheel locks up, its speed drops sharply. If this is ignored, the wheel stops much faster than the car. AT ideal conditions to stop at a speed of 100 km/h, the car takes about 5 seconds, but the wheel is locked in less than 1 second.

The ABS control unit knows that such a sudden interruption of movement is not possible, so it reduces the pressure on the brakes until acceleration begins, then again increases the pressure until repeated braking. This happens so fast that the wheel does not have time to change speed sharply. As a result, the wheels are braked at the same speed as the car, while the wheels are braked in a position bordering on blocking. In this case, the system achieves maximum braking force.

When the ABS is activated, you will feel the pulsation of the brake pedal; this is due to the rapid opening and closing of the valves. Some ABSs have up to 15 valve open/close cycles per second.

Types of anti-lock systems

Used in cars different types anti-lock braking systems, depending on the type of brakes installed. We will consider ABS by the number of channels - i.e. the number of valves that are controlled individually - and the number of speed sensors.Four-channel ABS with four sensors

This type is the best. Speed sensors are installed on each wheel, and a separate valve is installed for each wheel. With this type of ABS, the control unit controls each wheel individually to provide the highest braking force.

Three-channel ABS with three sensors

Usually this type is used on small trucks (pickup trucks) with ABS acting on all four wheels. The front wheels have two sensors and valves, one for each wheel, and one sensor and valve for the rear wheels. The rear wheel speed sensor is located on the rear axle.

This system provides individual control for each front wheel, providing maximum braking force. The rear wheels are tracked in pairs, i.e. both rear wheels must be locked for the ABS to work. This type of ABS allows one rear wheel to lock up when braking, which reduces its effectiveness.

Single channel ABS with one sensor

This type is usually installed on small trucks (pickup trucks) with ABS acting only on the rear wheels. Such an ABS has only one valve to control both rear wheels and one sensor located on the rear axle.

This type functions in the same way as the rear of the three-channel ABS. The rear wheels are tracked as a pair, i.e. both rear wheels must be locked for the ABS to work. This type of ABS allows one rear wheel to lock up when braking, which reduces its effectiveness.

This ABS is easy to recognize. It usually has one brake line going to both rear wheels via a tee. You can also find the speed sensor on the electrical connection next to the rear axle differential.

Frequently Asked Questions about ABS

Do I need to brake intermittently on a slippery road?When driving a car equipped with ABS, it is not necessary to brake by intermittent depressing the pedal. Intermittent brake application is used when braking a non-ABS vehicle to prevent wheel lockup and maintain vehicle control. In cars with ABS, the wheels never lock up, so intermittent pedaling will only prolong the stopping time.

When braking in an emergency on a vehicle with ABS, depress the brake pedal firmly and hold it down while the ABS brakes. You may feel a strong pulsation in the pedal, but that's how it should be, don't let go of the pedal.

Does the anti-lock braking system really work?

ABS makes braking more efficient. It prevents the wheels from locking up and provides the shortest braking distance on slippery roads. But does ABS help prevent accidents?

American Institute road safety conducted a series of studies to determine how often ABS vehicles are involved in accidents with fatal. The results of a 1996 study showed that ABS does not prevent fatal crashes. It has also been noted that vehicles with ABS are less likely to be involved in fatal crashes for the occupant of the vehicle with which the collision occurred, but more fatal for the occupant of the vehicle with ABS, especially in single-vehicle crashes.

For this reason, there is still debate about the effectiveness of ABS. Some people think that drivers of vehicles with ABS brake incorrectly and release the pedal when they feel it pulsing. Some believe that if ABS allows you to drive a car during emergency braking, then many in a fit of panic drive off the road and crash.

Recent studies show that vehicles equipped with ABS are less likely to be involved in accidents, but this is not yet a reason to believe that ABS improves driving safety.

ABS Component Layout

Let's put all the parts of ABS together and see how it works. The figure shows both an example and a close-up of the location of the ABS components in the car.- Burns, Robert - short biography

- The concept of common vocabulary and vocabulary of limited use

- Nancy Drew: The Captive Curse Walkthrough Nancy Drew Curse of Blackmoore Manor Walkthrough

- Deadpool - Troubleshooting

- Won't start How to Survive?

- What to do if bioshock infinite won't start

- Walkthrough Nancy Drew: Alibi in Ashes

- Spec Ops: The Line - game review, review Spec ops the line crashes on missions

- Room escape level 1 walkthrough

- Processing tomatoes with boric acid How much will 2 grams of boric acid

- Cucumber Grass (Borago)

- Bioinsecticide Lepidocid: purpose, properties and application procedure Lepidocide waiting period

- How to change the language to Russian in steam

- Dendrobium noble: room care

- Morphology of plants general concepts - document

- Planting, propagation and care of bamboo at home, photo Growing bamboo from seeds

- How to strengthen the cellular signal for the Internet in the country

- Sanskrit reveals the forgotten meaning of Russian words (2 photos)

- The oldest language Sanskrit programming language of the future Dead language Sanskrit

- Who has dominion over all the earth?