3d printer in modern life

We are all attracted to everything new and unusual. BUT the world just full of such unusual and original things. This is the reason why new business ideas are so well sought after. Although, as you know, everything new is a well-forgotten old. We are talking about a 3D printer or 3D printing technology. This technology is getting deeper and deeper into our reality. It is possible that at some time volumetric printing will be fully applied in all spheres of human life. But this is in the indefinite future, and in the present, the use of a 3d printer in business can bring not only significant benefits, but also good income. In addition, the competition in this area is still not very high.

Another huge advantage of this technology is the lack of dependence on physical spare parts. Stock shortage is immediately replenished by connecting to the network and sending the wrong part or machine to be printed. With a simple device, you can print products needed for everyday work, such as tools or utensils. However, the advancement of this technology is also expected to cause economic imbalances importance for developing countries. We believe that from now on it will be much cheaper, more convenient and easy to manufacture components and all kinds of objects.

What kind of beast is a 3D printer?

The technology of volumetric printing itself has existed for a relatively long time. The first experimental 3D printers were large. But today on sale you can find relatively compact models. What is this device? In fact, the device makes or "prints" three-dimensional objects from almost any material and shape.

Will these states continue to import their production? it last reflection is not trivial and can drastically exacerbate the problems of economic inequality between countries. Rich nations will get richer, and the poor will lower their expectations of change.

3D printing is set to revolutionize the industry. Architectural research and engineering companies have already benefited greatly from this advancement. However, although it is much more unknown, this technology has many and very surprising applications in the medical field.

Today, depending on the printer model, there are two ways to 3D print:

- laser;

- jet.

In laser printing, a laser is used as a tool, which can work both with a liquid polymer with its subsequent cooling, and with a powder material. As a result, the model that was breaded is obtained.

Some of these applications are still in the experimental phase, such as live cell extrusion, which has resulted in tissue bioimpression. Dentists have been the pioneers in creating implants using 3D printing, which is growing the most and is making some of the most exciting advances. This type of technology applied to dentistry increased the quality of parts and speeded up production.

One of them is the ability to create more compatible and customized bone implants at a lower cost. Recently, a three-year-old girl with hydrocephalus saved her life in China by transplanting a titanium skull obtained with this technique. This scientific and technical cooperation agreement involves the research institute of the center, IdiPaz, as well as area professionals and a German company. Traumatologists have discovered one of the most outstanding applications of this technology. It's about creating bone models that will work.

At inkjet printing a liquid polymer is used, which is affected by simple heating. Solidifying layer by layer, the polymer takes on the desired shape.

Surprising as it may sound, but you can find 3D printers adapted to the needs of cooking. They are stocked with food. What about a printer that can recreate a living organ?! Such a device will be simply indispensable in the field of medicine. The working material for it will be stem cells that people and animals have.

Thus, improvisation in surgical procedures is avoided, times in the operating room are reduced, and patient recovery is much faster. For the skin, Leiden University is developing a process that combines this technology with so-called induced stem cells to create this tissue.

You can see it on the university website. On the this moment this is the most remote application of modern possibilities, and it seems more science fiction. However, liver cell imaging is already underway and being investigated for drug testing. The American company "Organovo" is working on the creation of these organs, but in miniature only half a millimeter thick and 4 millimeters wide. This experiment is needed in the future to create larger structures, including the networks of ships needed to power them.

Software

For correct operation 3D printer requires appropriate software. And quite specific, since you need to get a simple picture, but an object of a three-dimensional form, which must correspond to all the specified parameters. In fact, there should be a whole complex of programs and 3d graphic editors that will control the machine and monitor the progress of its work.

The equipment is used for scientific research at the Institute and helped reduce costs and speed up work. This ability to develop important objects for the progress of research without relying on additional resources makes it much easier everyday life researchers. Today, we have the freedom to assemble the part we want without having to order it from other labs,” says Roseli Romero, coordinator of the Institute's Educational Robots Lab.

Some of the parts made by the printer were used in a Latin American robotics competition. The variety of applications offered by the printer has made it possible to develop parts that can be used on other sites. The quadritor, or drone, was built by printing parts of its structure. Today it is 100% functional,” the student explains. The drone already flies autonomously, has a linked camera, and reaches 200 meters in height, with its battery lasting an average of 30 minutes.

The price of such programs is considerable, but for simple devices there is a free analogue from Google- CatchUp.

Printer cost

Currently, there are various companies that sell printers for 3D printing. It is worth noting that when 3D printing first appeared, it was mainly used only in large enterprises. However, modern technologies have stepped forward so much that they have made it possible to produce 3D printers for small businesses or home use. The price for them, as a rule, is not more than 100 thousand rubles.

The doctoral dissertation said that new attributes could be included in the device: "Multiple sensors can be connected, and a quadritor can be used in multiple applications." Utilities - Through a partnership with the Brazilian Agricultural Research Corporation, the use of a quadriprotor in agriculture. Roseli explains that the idea is to use a drone to capture images of orange plantations to identify early variegated citrus chlorosis, a disease commonly known as yellow, one of the pests that most affect citrus. plants and work on disease prevention,” says the teacher.

Several factors affect the final cost of a printer:

- purpose;

- print permissions;

- print quality;

- print speed;

- availability of additional equipment and some others.

Also, the cost of the device is affected by the number of heads for printing and the dimensions of the working area.

Where to begin?

Another application of the equipment that is already being explored is its use for tracking Vehicle. Roseli explains that in this case, the drone could be used to monitor and search for vehicles, such as in police pursuit situations where authorities need to get to a running car.

However, the remaining material used after printing is still a problem. This scenario has led researchers to look for more sustainable alternatives, such as using plastic made with polylactic acid, which is 100% biodegradable.

Even the most interesting and promising idea cannot be successfully implemented without drawing up a correct and clear plan. Each entrepreneur should first familiarize himself with the various nuances that may appear along the way.

For this purpose, a business plan is drawn up. It should reflect all points, especially those related to costs (the cost of the printer, consumables, maintenance). It is also necessary to analyze the current state of the market situation. It is necessary to find out whether there is competition on the selected topic.

Our idea is to reduce leftovers. Therefore, we are exploring new opportunities, and the goal is to find raw materials based on renewable sources and biodegradable, - says the student. 3D printing has evolved exponentially since its first iterations conceived in those years. Since then, we've seen the forms and costs associated with prototyping, development, and even manufacturing on a smaller scale. With a fast and much less expensive process than other production methods, your business or industry has a lot to gain, don't you agree?

Cut your workflow down to half the time and achieve remarkable optimization in your designs, 3D printing can be all you need. Internal procedures have become more efficient, producing more cost-effective prototypes and more innovative business models. In addition, along with increased ability to customize products, companies are becoming more competitive. The level of customer satisfaction is expanding, and consequently, the company's revenues will be increased.

Produce the size of the planned profit. The resulting figure will allow you to judge how profitable the business will be. When drawing up a plan, be sure to consider advertising. This will allow you to determine initial capital, taking into account the cost of the advertising campaign. And it should not be neglected, because what is the point of “manufacturing” a quality product if no one knows about it!? In addition, advertising is a further good promotion for business.

3D printing can be used for various business initiatives. Here are six of the most popular. The importance of prototyping in development is almost immeasurable. Rapid prototyping is already making a difference in that it will change how well you can develop these processes, cutting down to half the development phase. Next, consider the three main types of prototypes.

With resolutions on the micron scale, the detail of the prototype reflects what might be the final product. To test with an investor or client to better communicate the product and prepare you to move out of development for your team, or even present your product to the world before it's official release, 3D printing gives you the means to replicate your designs with precision.

In order to ensure the functionality of prototypes related to the verification of functionality, consideration should be given to the successful use of the product in question, including in some cases ergonomics.

Souvenir products and accessories

With the help of a 3d printer, you can make various souvenirs. You can choose almost any topic. You can rely on the themes that the film industry adheres to and which is the most popular among the children's audience. It could be your favorite cartoon characters.

In addition to fittings and internals, we've adapted the motor to run through a stepper motor found in 3D printers, check out this story.

Compared to removal production methods, as with milling and turning machines, 3D printing differs in that it is a complementary production method. That is, the consumption of printers is proportional to the created model only, without losing material. And so you can produce more!

However, in addition to cartoon characters and movie characters, including famous monsters (alien, predator, and others), you can print figurines famous actors. Some enterprising businessmen just based their activities on this. Miniature models of famous figures (politicians, sports stars, show business and other personalities) will also look good. How nice to have in your collection a figurine of the president himself!

The economy, both time and investment, is virtually immeasurable. Companies can adopt technology methods in which the designed model is accurately recreated within hours, meaning more products are launched in less time.

You can see other companies that are enjoying this booming market. I happily assured my partner that we had indeed learned something. Since we have learned with certainty that this cannot be done, we need to find another.

More iterations bring more improvements. Each production area has a large number of competitors looking to capture ever larger market segments, innovation dictates who gets the most market share, with innovation tools you have the means to ensure your product launches first, more refined and with less hassle. For innovation above all, your product first, more refined and with the least difficulty is paramount to fail at the start of a project cheaply, providing the necessary time for improvement.

No less common and in demand are the figures of the newlyweds. By the day of the wedding, this will be the most wonderful gift that will remain in memory for a lifetime, as it will personify the young themselves.

If you have a printer, this is the easiest and effective way start your business. There is nothing complicated here - all you need is to take some kind of three-dimensional image, and the device will do the rest by itself. Otherwise, certain resources are needed.

The importance of the error margin has a big impact because failure is closely related to improving or creating a new quality product from scratch. 3D printing is available so you can create multiple prototypes before reaching the final model without spending huge money or time.

In addition to specific applications, 3D printing still reduces the development time of any type of prototype, as it allows for a dynamic development method consisting of build, test, validate, and iterate during product validation, a marked increase in productivity, and the creation of better versions of the product, ensuring, that your product reaches the market in the best possible condition.

On the 3D printer, in addition to souvenirs, there are various accessories. Many people have Cell Phones, and therefore it is possible to move in this direction. Moreover, you can “print” them according to your own sketches or according to sketches of clients. The printer not only allows you to print almost any form, most importantly, it is able to realize everything that can be born in our head.

In addition to accessories, you can try to make cases or cases for mobile devices in this way. No less attractive will be key rings for the keys to the house, work, car. For example, a miniature figurine exactly the same as the car itself will look good as a keychain for car keys. Engaging in such a business will not be how profitable, but how interesting.

Decorations

With the help of a 3d printer, you can make good decorations for any holiday or celebration. At the same time, each product will differ in its style and originality. This is where you can show your imagination in all its glory. You can make original Christmas decorations, which cannot be found in stores (figurines of miniature Christmas trees, balls, hearts and many others).

What about jewelry? Modern 3D printers can already work with materials such as:

- gold;

- silver;

- platinum;

- stainless steel;

- colored nylon.

In other words, you can make the same products that any jewelry store usually offers. And if we take into account that the shape of the decoration can be chosen as the customer wishes, then its cost will not be lower than the market value. At proper organization business, the income will be substantial.

An example is the Zazzy service, which is just making jewelry on a 3d printer.

Design and architecture

3D printing as a business in the field of design and architecture will be simply an indispensable find. The fact is that when creating a three-dimensional model of an object on a computer, it is not always possible to make an objective assessment of it. And by recreating its voluminous version from a physical point of view, you can identify possible disadvantages. Such a visual demonstration will allow more flexible work with the model, taking into account the new possible wishes of the customer.

For students studying architecture, a 3D printer will allow them to present their future project in all its glory. If necessary, you can create entire neighborhoods or even a small town.

Beginners either professional designers can use a 3d printer to produce various decorative items for any interior. Each of them will be so unique that it will bring additional comfort.

3D text

For some time it was popular to put an image or inscriptions on a cup or even a plate. Anything could be used as an image, including your own photo. Using the printer in question, you can apply voluminous text to the same mug or plate. In addition, such mugs can be given to all participants of an event as a gift.

It will also be a good gift for a birthday with a corresponding congratulatory inscription.

Nuances of 3D printing

Using a 3D printer as a business is a great idea, but there are a few things that need to be cleared up before getting started. You need to be clear about the challenges you will face.

Despite the fact that today 3d printers differ more modern technology, not everything is subject to printing. Significant limitations are the print resolution, as well as the size and complexity of the geometry of the desired object.

Desktop printer models are not capable of printing complex assembly mechanisms. There are also color restrictions. Multi-color printing can only be performed by industrial-scale devices so far. All the rest, in the presence of two extruders, are able to reproduce only two colors, and without a smooth transition.

After printing objects, they often need additional processing (both mechanical and chemical). Therefore, it is worth making stocks of sandpaper, files, solvents.

Conclusion

The use of 3D printing in small businesses is a good idea. Do not just try to compete with mass production. Using a desktop printer, you can produce truly original products that will always be in price.

Creating a physical 3D object from a digital prototype using a practically portable device, a 3D printer, opens up many interesting opportunities in creativity, art, science, business, other areas of human activity, and even just in everyday life.

At the current stage of development of additive technologies (layer-by-layer synthesis technologies) in the field of rapid prototyping and production of 3D objects, the possibility of their use at home or in small-scale production is already more than available. Acceptable prices for the devices themselves, for their maintenance and for consumables attract enterprising and simply enthusiastic people interested in developing a small business or home creativity.

In the review, under the concept of “home printers”, devices of the lower price categories are considered, i.e. the cheapest 3D printers for home or small workshop, small office, and only those that you can easily buy in Russian Internet-shops. The 3dprint.tkat.ru catalog contains and grouped offers from Russian online stores selling 3D printers.

In such devices, the method of modeling objects is most often used by layer-by-layer fusing of the working material (mainly plastic threads, in some models - metal, wax, plasticine, clay, ceramics), supplied by an extrusion head to the platform. This technology is abbreviated as FDM, which stands for fused deposition modeling. The most common types of plastic used for FDM are ABS (ABS - Acrylonitrile Butadiene Styrene, impact-resistant and elastic, durable, but subject to degradation under ultraviolet radiation) and PLA (PLA - Polylactide, the most environmentally friendly and biocompatible thermoplastic polyester made from sugar beet or corn waste, however, it decomposes rather quickly)

1. Overview of the possibilities of home 3D printers

1.1..Rapid prototyping. Today, even the cheapest and simplest desktop 3D printer, bought at a discount as substandard (after being conditioned, of course), can print 3D model made of plastic with an accuracy of 100 microns. In this case, a person participates only as a computer operator, and the printed object will be an exact copy of a 3D computer model. This is a huge potential for creativity and art. For modeling, prototyping and practical purposes, you can print models of inventions, technology, buildings, furniture, accessories, various household devices and appliances that you can’t buy in a store. You can print gifts for family and friends: souvenirs, jewelry, designers, toys, etc.

1.2..self-reproduction(replication). The so-called RepRap project. The project involves the creation of a printer that can fully reproduce itself, that is, all its details. There are now RepRap printers capable of 50 percent self-replication and just over fifty.

1.3..Seal of weapons for 3D printer. In principle, it is possible to print a combat pistol, and a knife, and brass knuckles, and a halberd - such precedents already exist. But detailed description we will omit these opportunities as unnecessary, since the manufacture, alteration and repair of weapons provides for criminal liability with terms of imprisonment of up to 8 years. Print models, but not military weapons.

2. A brief overview of several budget models

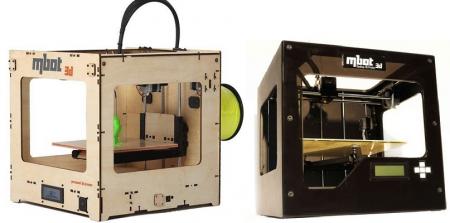

2.1... The manufacturer offers two models, MBot Wood Double Head(in a wooden case) and MBot Cube II(in the steel case with a dusting). These printers have two or one extrusion heads, depending on the modification. Two heads make it possible to print in two colors at the same time, which, of course, belongs to the advantages of the device. The minus experts call the lack of a guarantee and difficult feedback with the manufacturer, the Chinese company Magicfirm. In general, both models are rated at an average of 7-8 points out of 10. The Mbot Cube home 3D printer works with ABS and PLA materials. The diameter of the fiber used is 1.75 mm. The print speed is approximately 40 mm/s. With this speed, a medium-sized object like a hull mobile phone printed in just over an hour. The maximum possible volume of the printed object is 8 and almost 12 liters (200 x 200 x 200 mm for MBot Wood Double Head and 260 x 230 x 200 mm for MBot Cube II). To control the device there is a liquid crystal non-touch display. Both devices come with power supplies, USB cables, SD card, software for OSX/Windows/Linux, trial consumables. WiFi connection and connecting flash drives are not supported.

2.2.. 3D printer PP3DP UP! Plus 2. One of the pioneers of home 3D printers supported by the Windows 8.1 platform. For those who have this installed on their computer operating system, no need for special software and drivers. Complete with Win 8.1, all this is already there to work with Up! Plus 2. From the previous modification, UP! Plus, this model looks slightly different, left open design(By the way, this is not very good for printing with ABS plastics, since they require a constant uniform temperature, but it is good for printing with PLA plastics). On the other hand, the engine and wiring system have been significantly improved, platform calibration has been fully automated, which is important, especially for beginners. Both models, despite the fact that they have one extruder each, can print in different colors. To do this, in the new software, from version 2 and higher, it is possible to stop printing, change the color of the plastic and resume printing with a new color. Connection to the host computer via USB only. With a light weight and dimensions, a one-year warranty, this printer is perfect for home use. The print volume is 140 x 140 x 135 mm, which is 2.7 liters, significantly less than the MBot. ABS and PLA filaments are used for printing, and the ABS plastic spool is included with the printer (this is logical, it is also cheaper than PLA). On average, this printer is rated 6.5 out of 10.

2.3.. and MyRiwell 3D printer RL-200A . Chinese 3D printers in a bright, presented in different colors, closed case. The closed design is a major plus when printing with ABS plastic. But, on the other hand, it is harder to print with PLA plastics, since there is not enough air mass circulation, even if you print with the lid open. Printing accuracy (resolution) - 150 microns, print volume 225x145x150 mm (4.9 liters). These are good parameters for this class of devices. However, in reality, these parameters, due to the design features, are not used to the full, print with high quality problematic on this printer. It is advisable to use it only at home, for the industrial quality of 3D prototyping, it does not hold out. On average, you can rate this printer 6 points out of 10.

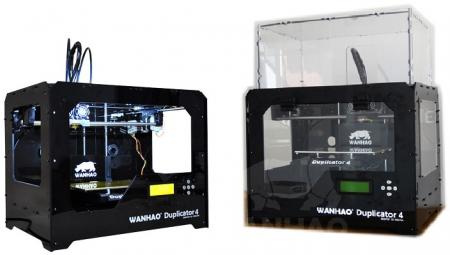

2.4.. WANHAO Duplicator 4 3D printerand. The second one differs from the first one only by the presence of a heat chamber on top of the main body of the body, which maintains the optimum temperature in the printing area to prevent delamination, deformation and delamination of the 3D model. Both modifications are the Chinese version of the American MakerBot Replicator 2. The Chinese have achieved almost the same characteristics as the American prototype, but won the attention of buyers at half the price. Like the Americans, the Chinese use nozzles of a fairly large diameter, 0.4 mm, in their duplicator, which is too much for high-quality 3D printing. The Americans compensated for this shortcoming with flexible software, and the Chinese with the low price of the printer. Both modifications of the Duplicator are available in three types of cases each, or rather in cases made of different material– plastic, wood and metal. And in each of the buildings place the filling with one or two extruders. It is clear that with two extruders, color, or rather even multi-colored printing is available. Color is also available with one extruder, when using multi-colored plastics. In addition, unlike the Replicator 2, the Duplicator 4 and 4X use the method of heating the working platform, which improves the print quality of both PLA and especially ABS filaments. By the way, using this function in many cheap 3D printers and, accordingly, the ability to print with ABS plastic, manufacturers also attract buyers. On a 10-point scale, 4 and 4X score 6 and 7 points, respectively.

2.5..3D pens- These are devices that allow you to literally draw in the air with molten plastic, which solidifies upon contact with air. In addition, with the help of a 3D pen, you can correct the flaws that are possible when using a 3D printer.

One of the most popular models is the American 3Doodler 3D pen. Its weight is only 150 grams, and its size is 4.5 by 17.5 cm. The thickness of the consumable plastic thread is 3 mm. There are buttons for controlling the speed of printing, plastic feed, as well as a key to stop printing. When working with the device, the temperature of the tip of the pen reaches 270 degrees, which causes the rod to melt. The material instantly hardens upon contact with air, which allows you to create shapes of any shape.

A pretty strong competitor to 3Doodler is the 3DYAYA 3D Pen Chinese origin. It has a thinner expendable core - when printing, a plastic thread with a thickness of 1.75 mm is used. Such a pen also, like 3Doodler, has buttons for feeding plastic, immediate stop printing and speed control. The 3DYAYA 3D pen has a patented cooling system.

The RainSun 3D pen has almost the same dimensions as 3Doodler and 3DYAYA, but the body is safer, since the plastic feed control button is located much higher than the extruder nozzle, which eliminates the possibility of burns. Cooling is carried out by means of a fan, the rotation speed of which depends on the intensity of heating. The disadvantage of this pen is the inability to select the heating temperature of the plastic, so only ABS plastic can be used in it.

The Lix 3D Pen is the smallest pen in existence, measuring just 1.40cm in diameter and 16cm in length. The refill is 1.75mm thick. One of the advantages of this pen is that it is powered via USB, which allows you to charge it from a computer or laptop. A pen of this size is very convenient, but it has one obvious disadvantage - after printing a 15-20 cm line, you will have to insert a new consumable rod.

Relatively new model- 3D pen from MyRiwell. This pen has a number of advantages over its predecessors. A replaceable nozzle allows you to change the thickness of the line from 0.4 to 0.7 mm, and a power supply with a fuse will protect the pen from damage caused by power surges. In addition, the MyRiwell handle stops heating up if not used for 7 minutes. There is also a function to adjust the heating temperature of the plastic.

Unfortunately, there are still not enough reviews of real users of personal 3D printers on the network to fully objectively assess their capabilities. At the current stage, one has to make a purchase decision based on the properties and characteristics declared by manufacturers, the published results of a few practical experiments conducted by initiative experts. As information is collected, this review will be supplemented and adjusted so that interested consumers have more information to make a decision. One thing is indisputable - 3D technologies are developing rapidly and are being introduced into our everyday life, simplifying it and adding variety to it.

- Burns, Robert - short biography

- The concept of common vocabulary and vocabulary of limited use

- Nancy Drew: The Captive Curse Walkthrough Nancy Drew Curse of Blackmoore Manor Walkthrough

- Deadpool - Troubleshooting

- Won't start How to Survive?

- What to do if bioshock infinite won't start

- Walkthrough Nancy Drew: Alibi in Ashes

- Spec Ops: The Line - game review, review Spec ops the line crashes on missions

- Room escape level 1 walkthrough

- Processing tomatoes with boric acid How much will 2 grams of boric acid

- Cucumber Grass (Borago)

- Bioinsecticide Lepidocid: purpose, properties and application procedure Lepidocide waiting period

- How to change the language to Russian in steam

- Dendrobium noble: room care

- Morphology of plants general concepts - document

- Planting, propagation and care of bamboo at home, photo Growing bamboo from seeds

- How to strengthen the cellular signal for the Internet in the country

- Sanskrit reveals the forgotten meaning of Russian words (2 photos)

- The oldest language Sanskrit programming language of the future Dead language Sanskrit

- Who has dominion over all the earth?