River sand conversion from tons to m3. How to determine the bulk density of sand

Sand is loose natural material, obtained as a result of natural destruction rocks under influence external factors. It may contain a small amount of various impurities. It is used in almost all types of construction. To properly mix the solution, you need to know the density of the sand, since the proportions of the remaining components depend on it. It also affects the volume of purchases, for example, for arranging a pillow under the foundation.

What is density and what does it depend on?

Density shows how many grains of sand in kilograms are placed in 1 m3. It is measured in kg/m3, sometimes in t/m3 or g/cm3. But this value is not always constant, as it can change depending on the following conditions:

1. Grain size. It happens fine-, medium- and coarse-grained. The larger the grain of sand, the lower the density, and, conversely, the finer ones fit more densely. Coarse and medium-sized sands are used for the manufacture of building materials and masonry mortars, while fine-grained sands are used for the production of dry building mixtures.

2. Porosity. Shows the number of voids. The high porosity option has a lower density. If it is loose, then the value is 47%, if compacted - 37%. The degree of porosity decreases when the sand grains are saturated with moisture, as they are enveloped in water and the voids between them disappear. It also decreases after transportation, as during movement everything is compacted due to vibration. Different fractions have different degrees of porosity. For building sand from large and medium grains, it is 0.55, for fine sand - 0.75. The tighter it is packed, the heavy load from the foundation is able to withstand and distribute it more evenly.

3. Moisture coefficient. Before buying, be sure to check the degree. The more water it contains, the lower the density. The weight of 1 m3 of raw sand differs significantly from the same amount of dry sand.

4. Impurities. Depending on their volume, the density of sand kg/m3 also changes. It may contain clay, dust, salt, gypsum and more. The density of pure material is about 1300 kg/m3, with clay impurities - 1800 kg/m3. To remove contaminants, it is washed, but because of this, the cost increases markedly.

Types and prices

There are several types of densities:

- true;

- bulk (medium).

The first type is otherwise called specific gravity, it is also measured in kg / m3. The true density shows how much is in one cubic meter of bulk building material, without taking into account the voids between the grains. Calculate it in laboratories empirically. Its value for non-metallic sandy rock is 2500 kg/m3.

Bulk density shows the amount in one cubic meter, taking into account voids and gaps. Its value is always less than the true value. To measure it, you need a bucket of 10 liters. Sand in the usual uncompacted state is poured from a height of 10 cm from the edge of the container, until a slide appears above it. As soon as the bucket is full, the excess is leveled with a metal ruler, without compacting the sand, after which the container is placed on the scales. The result obtained must be divided by the number 0.01, which means the volume of the bucket, translated into Cubic Meters. For example, sand weighs 16.5 kg, its compaction coefficient is: 16.5/0.01=1650 kg/m3. In this case, it is convenient to use the formula P=M/V, where P is the density, M is the mass, V is the volume. And, conversely, knowing the compaction index, it is calculated how much the bulk building material weighs, for this it is multiplied by the volume of the container - M \u003d P * V.

The true density of building sand is a constant value. For calculations, the average value is used. Prices vary depending on its type, purity and size of fractions. Uncleaned is much cheaper than washed. Therefore, if a small batch is required, then unwashed sand can be purchased and cleaned of impurities on its own, especially if it is necessary for the construction of an unloaded structure. If you need to make a foundation, then you should purchase only clean and high-quality material. Clay and other impurities reduce the degree of adhesion of grains of sand to cement, which reduces the strength grade of concrete.

Table with prices at which you can buy building sand:

When choosing sand, one should take into account: the lower its density, the more binder powder is required to fill the voids between the grains of sand and connect all the components, as a result, the cost of the mortar increases.

The degree of radioactivity of most bulk building materials is the first, but it is better to check the quality certificates, especially if it will be used to build a house, in this case only the first class should be.

If you plan to build a house, then after creating the project, the issue of acquiring materials comes to the fore. To calculate how much sand to buy to mix the required volume of masonry mortar or concrete mix, you need to know the density of the bulk component. This indicator significantly affects the strength parameters of structures and buildings. The conversion of mass into volume (and vice versa) is also carried out because the price of the material is indicated in different ways: per weight or volume unit.

What is density and what does it depend on

This is a physical characteristic of a substance, showing the mass of its unit volume and expressed in g / cm3, kg / m3, t / m3. Sand, like all bulk materials, has the following feature: depending on the conditions, the same amount of sand can occupy a different volume. The density index of building sand is influenced by the following factors.

1. Grain size (fineness modulus). Sand is a mixture of particles ranging in size from 0.14 to 5 mm, formed naturally in the destruction of rocks. The smaller the grain size and the more uniform the composition, the denser the sand. Coarse and medium-grained material is used for the manufacture of concrete, fine-grained - for cement mortars, fine-grained (pulverized) - for building fine mixtures.

2. Porosity and level of compaction. They characterize the number of voids in the bulk material. In a loose state, building sand has a porosity of about 47%, in a dense state - no more than 37%. Looseness is reduced due to saturation with moisture, vibration, dynamic effects. Porosity is estimated using a special coefficient e: for fine-grained sands of dense composition, it is about 0.75, coarse and medium-grained - 0.55. The compacted sand mass takes on quite high loads and well distributes the stress arising in the foundations.

3. Humidity. Usually, reference books give density at a normal humidity level, regulated by GOST. When buying, it should be borne in mind that the weight of a cubic unit of raw material differs significantly from the theoretical indicator. With an increase in humidity from 3 to 10%, the grains of sand are enveloped in water - due to this, the volume increases, and the density, respectively, decreases. With further moisture saturation (up to 20%), water displaces air and fills the voids between the grains - while the weight of a cubic meter increases.

4. The presence of impurities. Sometimes contains particles of clay, dust, salt, mica, gypsum, humus, crushed stone, stone chips. They affect the quality building material a: if for pure sand it averages 1,300 kg/m3, then for clay sand it is 1,800 kg/m3. Sand can be cleaned by washing with water, but this increases its cost.

Types of density

Building sand can be characterized using different indicators of its volumetric weight: theoretical and actual.

1. True (former name - specific gravity). This is the mass of a cubic meter in an absolutely compacted state, without taking into account the air gaps between the particles. The true indicator is determined in a complex laboratory way, its value corresponds to the weight of a cubic meter of solid non-metallic sandy rock - approximately 2500 kg / m3.

2. Medium (bulk). When determining it, it is taken into account that the calculated volume includes not only grains, but pores and voids that fill the gaps between them. The average is usually below the true value.

To independently determine the average density, use a bucket with a capacity of 10 liters. Sand is poured into it from a height of 10 meters until a hill forms - it is carefully cut horizontally at the level of the upper edge of the bucket. The material that fits in the container is weighed, and then its density is calculated in kg / m3: divide the mass in kg by 0.01 (the volume of the bucket in cubic meters).

The true value is a constant value and has an auxiliary value. In order to competently conduct construction, make practical calculations and evaluate the quality of the purchased material, it is more important to know the average. For example, if a cubic meter weighs less than 1300 kg, this indicates in large numbers voids and requires their filling with a binder. At the same time, the cost of materials increases, making construction more expensive.

Density of various types

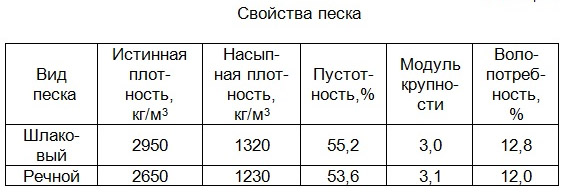

The approximate indicators of bulk (average) density indicated in the table will help you purchase sand with the necessary parameters, quickly switch from weight to volume, and calculate the weight fractions of the mortar.

Sand is a popular building material used in the preparation of mortars. But for each type of work there is a type of material, characterized by its own indicators.

One of these is bulk density, which will be discussed later.

There is such a statement that the value of the density of the presented material is directly dependent on the structure of the grains. If this setting is too high value, which means that grains of sand are present in the grain structure, which can be characterized by high density and strength.

It is he who has such characteristics that is used in the production of high-strength concretes, which have high level resistance to low temperatures.

Now it's time to deal with the types of sand. Distinguish:

The presented parameter according to GOST 8736 93 for construction can be of three types: true, bulk and average. A very important criterion on which the voidness and humidity depends is the average density of the sand.

You can learn about how gravel differs from crushed stone and see it in the photo in this

Today, construction has a density of 1.3-1.8 t / m3. It all depends on the presence of impurities in the product. The larger their number, the higher the presented indicator. Thanks to this figure, it is possible to determine the quality of the grain composition.

For river sand, the average density is 1.3 t/m3. The mineral composition of the product is directly related to the geographic location of the mine. Despite this, river sand is considered the purest material, which does not contain impurities.

In practice, the bulk weight and the bulk specific value of the parameter under study for a specific volume of bulk material, which is placed in containers with dimensions of 1x1x1m, are in great demand. To determine its specific gravity, it is necessary to know the value of the particle size modulus.

For a small river, a large value of the parameter under study is characteristic, in contrast to a coarse-grained building product. Its percentage of moisture can affect the specific gravity. This material is characterized by a specific gravity of 1200-1700 kg/m3. As a result, we can draw a line and say that the following properties influence the presented indicators:

- mineral composition of bulk material,

- his faction

- degree of humidity.

You can find out about the weight of crushed stone of fraction 20 40

When the humidity level environment rises, then the density of the sand in it will decrease. The reason is that grains stick together. The indicator will decrease until the degree of humidity drops to 10%.

Wet differs from dry in that the former has a low density and an increased volume. After that, the process of increasing the liquid in the structure of the product is carried out, as well as an increase in the studied indicator due to the coating of each granule with a thin layer of water. The presented feature is taken into account when dosing the building material in terms of its volume. If the humidity level rises, then all intergranular voids are filled with water, air is displaced, and the density increases again.

What is the price of crushed stone fraction 40 70 indicated in this

On the video - bulk density of sand kg m3:

You can find out which one by reading the article.

The bulk density of building sand is a very important parameter. This criterion is influenced not only by the composition of the material, but also by the level of humidity. You can calculate the bulk density of sand yourself. In addition, for each type of product presented, the density takes on its own values. According to the value under study, it is possible to determine the quality of the granules and thereby obtain high-quality and reliable concrete.

- Burns, Robert - short biography

- The concept of common vocabulary and vocabulary of limited use

- Nancy Drew: The Captive Curse Walkthrough Nancy Drew Curse of Blackmoore Manor Walkthrough

- Deadpool - Troubleshooting

- Won't start How to Survive?

- What to do if bioshock infinite won't start

- Walkthrough Nancy Drew: Alibi in Ashes

- Spec Ops: The Line - game review, review Spec ops the line crashes on missions

- Room escape level 1 walkthrough

- Processing tomatoes with boric acid How much will 2 grams of boric acid

- Cucumber Grass (Borago)

- Bioinsecticide Lepidocid: purpose, properties and application procedure Lepidocide waiting period

- How to change the language to Russian in steam

- Dendrobium noble: room care

- Morphology of plants general concepts - document

- Planting, propagation and care of bamboo at home, photo Growing bamboo from seeds

- How to strengthen the cellular signal for the Internet in the country

- Sanskrit reveals the forgotten meaning of Russian words (2 photos)

- The oldest language Sanskrit programming language of the future Dead language Sanskrit

- Who has dominion over all the earth?